Station De Fer À Souder I2c Micro Jbc Nano 110/220v Avec Jbc C245 C115 C210, Pour La Réparation De Téléphones, Outil De Soudage De Pcb - À Souder Stations - AliExpress

Stations de soudage numérique pour les professionnels | Composants électroniques. Distributeur et magasin en ligne Transfer Multisort Elektronik

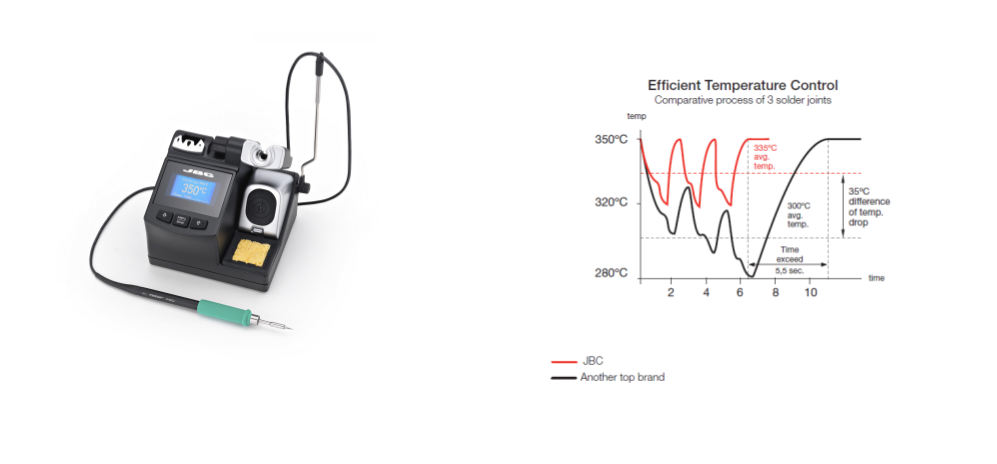

Station de soudage compacte avec fer à souder T245-A pour usage général CD-BE JBC JBC-CD-2BE : JBC: Amazon.fr: Bricolage

Station de soudage compacte avec fer à souder T245-A pour usage général CD-BE JBC JBC-CD-2BE : JBC: Amazon.fr: Bricolage

Station de soudage de caractéristiques sans LED pour réparation de soudure PCB, poignée universelle I2C 2SCNi

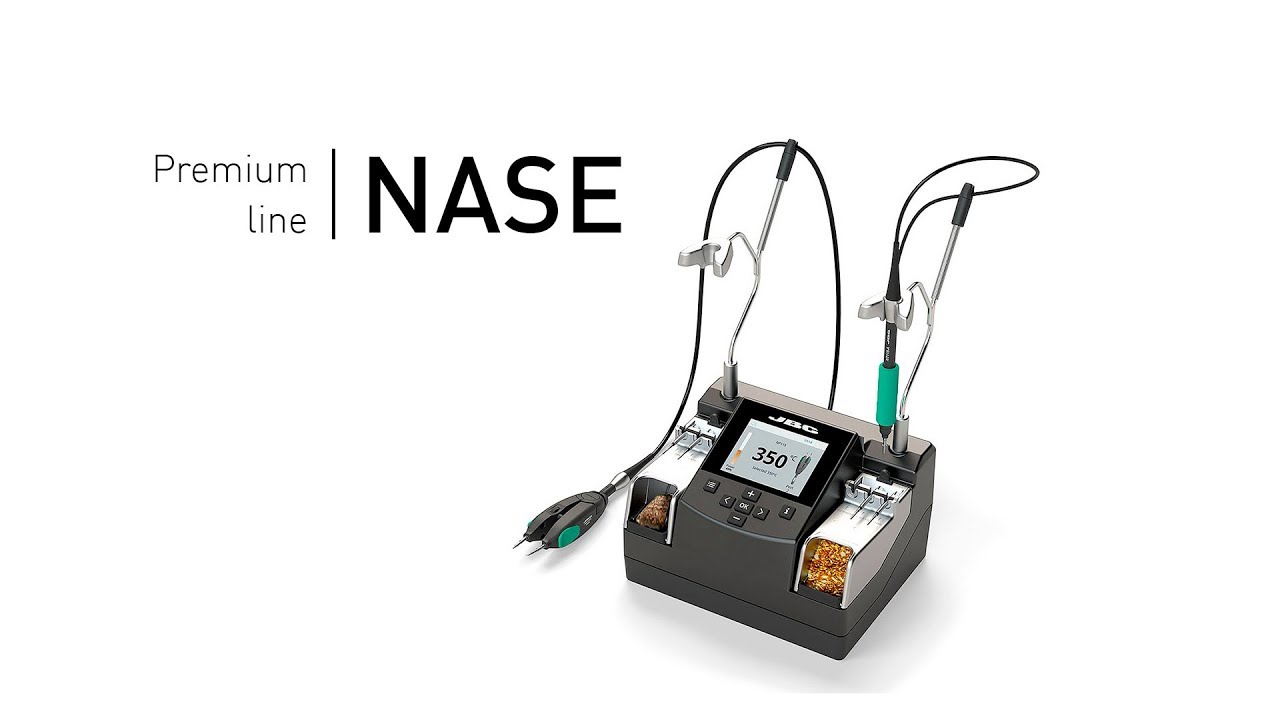

A902 Station de soudure Jbc C115 C210 C245 Station double Station de soudage Station de retouche pour téléphone portable Pcb Ic Réparation Outils de soudure | Fruugo FR

Jbc – Station De Soudage 110v/220v, Originale, Avec Poignée, Pour La Réparation De Cartes Mères De Téléphones Portables - À Souder Stations - AliExpress